Recent Articles

Torque Tool Calibration: The Paperwork That Protects

If you’re lining up maintenance near Toledo, Ohio, calibration isn’t busywork—it’s schedule insurance. Industrial Bolting provides torque tool calibration services in Toledo and the surrounding communities, helping crews keep flange joints, heat exchanger covers, turbine hardware, and structural bolts moving forward—without the dreaded redo.

Induction Bolt Heating: When Fasteners Won’t Budge

If you’ve ever walked into a shutdown and found studs that feel “one with the flange,” you know how quickly corrosion, heat cycles, and time can turn a simple heat exchanger cover into an all-shift battle—this is where induction bolt heating can change the pace. Industrial Bolting provides induction bolt-heating services throughout the Midwest, helping […]

Hydraulic Torque Wrench Rentals: Tool Kit Basics

If you’re lining up hydraulic torque wrench rentals for a turnaround or shutdown, you don’t have time for missing parts, mismatched fittings, or a “where’s the reaction arm?” scramble. Industrial Bolting supports crews in Westfield and Merrillville, Indiana; Muskego, Wisconsin; Toledo, Ohio; and Alton, Illinois, shipping rental-ready systems that arrive organized and jobsite-tough—so you can […]

Hoosier B-RAD Torque Gun Rentals: Pick the Best Drive Type

If you’re scheduling shutdown work in Indiana, the last thing you want is a torque tool that slows the line. Industrial Bolting supports crews across the state—especially around Westfield and Merrillville—with fast, job-ready RAD/B-RAD gun rentals that help you move from staging to bolting flange joints, exchanger hardware, turbine-area connections, or structural bolts without dragging […]

Torque and Tension Training for Crews: Stop Bolting Mistakes

January is the month when maintenance budgets meet the reality of outages. You can plan every minute of a turnaround—and still lose hours to one thing: rework at the joint. A leaking flange, a stripped stud, or a snapped bolt doesn’t just slow a crew down; it can bring a project to a halt. It […]

Torque Tool Rental Guide for Plant Maintenance

January is when Q1 maintenance budgets meet real-world outage schedules. Lead times shrink, crews get committed, and big-ticket work shows up quickly—often before procurement is ready. For projects across the Midwest, especially in Indiana, Illinois, Ohio, and Wisconsin, Industrial Bolting offers responsive field support, certified technicians, and flexible torque tool rental options that help teams […]

Same-Week B-RAD Rentals for Midwest Turnarounds

Industrial Bolting knows January outages come with a familiar challenge: do it fast, do it right, and document it. Whether you’re breaking flanges on a heat exchanger, checking turbine hardware, or verifying structural connections, the right torque tool makes the difference. If tool delays threaten your window, our same-week B-RAD gun rentals help you keep […]

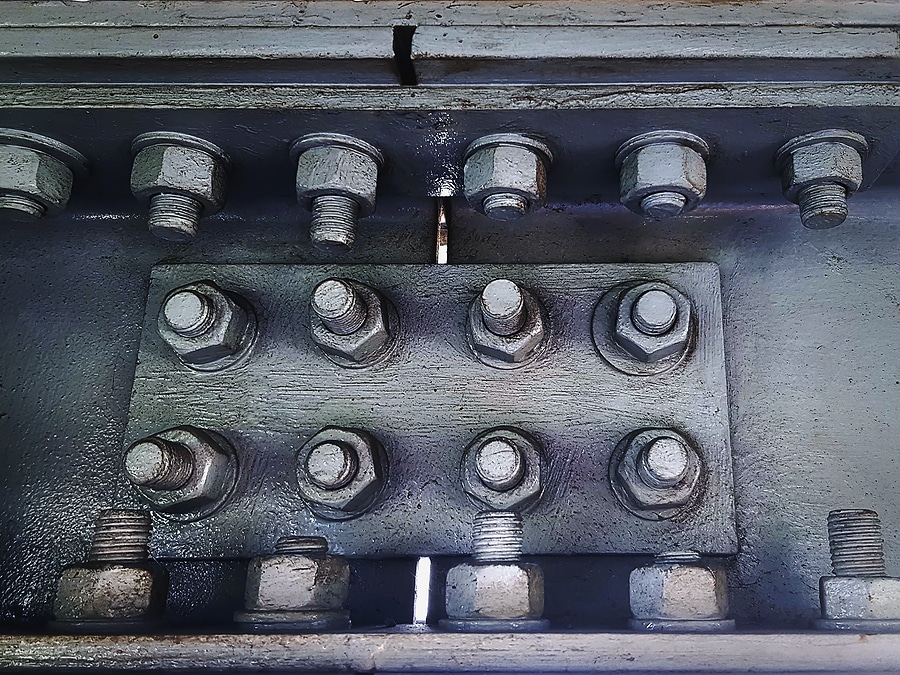

Controlled Bolting Services for Industrial Turnarounds

January is when outage calendars fill up fast—budgets reset, maintenance plans sharpen, and in the Midwest, winter conditions add another layer of complexity to already tight turnaround schedules. If your team is planning Q1 shutdowns, now is the time to lock in controlled bolting support before crews, tools, and field specialists book out. Industrial Bolting […]

Avoid Cold-Weather Torque Errors This Winter

Winter conditions can take a serious toll on industrial tools. At Industrial Bolting, we often see an increase in torque-wrench performance issues during colder months—especially in Indiana, Illinois, Ohio, and Wisconsin, where rapid temperature swings are common. Cold weather does more than make jobsites uncomfortable; it can directly affect torque accuracy, reliability, and tool lifespan. […]

Scale Aerospace Assembly with Hydraulic Torque Wrench Rentals

Across Indiana and the greater Midwest, aerospace manufacturing continues to accelerate. New aircraft programs, supplier expansions, and rising demand are pushing assembly lines to operate faster and more efficiently. Industrial Bolting supports aerospace manufacturers throughout Indiana, Wisconsin, Ohio, and Illinois, helping teams adapt to changing production requirements with short-term hydraulic torque wrench rentals. As production […]