Category: Torque Tool Calibraiton

Avoid Cold-Weather Torque Errors This Winter

Winter conditions can take a serious toll on industrial tools. At Industrial Bolting, we often see an increase in torque-wrench performance issues during colder months—especially in Indiana, Illinois, Ohio, and Wisconsin, where rapid temperature swings are common. Cold weather does more than make jobsites uncomfortable; it can directly affect torque accuracy, reliability, and tool lifespan. […]

Powering Hoosier Wind Projects with RAD Dual Turning Gear Kits

For decision-makers overseeing turbine installation, commissioning, and long-term maintenance, having reliable, high-precision torque tooling is critical. Industrial Bolting supports wind energy projects across Indiana and the greater Midwest with RAD wind turbine turning gear kits and RAD torque gun rentals and sales designed to meet the demanding requirements of modern wind turbines.

Understanding Hand-Arm Vibration Syndrome in Bolting Operations

In heavy-industry bolting operations, torque tools deliver critical performance — but those same tools can also pose serious health risks. At Industrial Bolting, we help companies understand and manage one of the most significant concerns related to vibration exposure: Hand-Arm Vibration Syndrome (HAVS). HAVS is a cumulative occupational injury caused by repeated vibration exposure, making […]

Cold Weather, Hot Problems: Diagnosing Torque Tool Issues Fast

Industrial torque tools are built for demanding environments, but even the most reliable equipment eventually shows signs of wear. As colder temperatures settle across the U.S.—especially throughout the Midwest—hydraulic and pneumatic torque tools become more susceptible to performance issues. At Industrial Bolting, we provide expert torque tool calibrations and understand how winter conditions can thicken […]

The Hidden Cost of Improperly Torqued Bolts in Heavy Industry

Across heavy industries—manufacturing, power generation, construction, and mining—one small mistake can trigger major consequences: improperly torqued bolts. Industrial Bolting, with locations in Indiana, Ohio, Illinois, and Wisconsin, recognizes the critical role precision plays in every bolted connection and helps crews prevent torque errors before they become costly problems. Even minor torque deviations can cause bolts […]

The Importance of Torque Tool Calibration in Cold Weather

Industrial Bolting offers torque tool calibration services throughout Indiana, Illinois, Ohio, and Wisconsin. As seasonal conditions shift, our team helps industrial crews maintain the accuracy and reliability of their equipment. With winter approaching, proper calibration ensures hydraulic, pneumatic, and manual torque wrenches perform with the precision needed to keep both workers and machinery safe.

Industrial Bolting: Trusted Industrial Tool Service and Support

In heavy industries where precision, safety, and uptime are critical, reliable support is essential. That’s why companies across America turn to Industrial Bolting. More than just a torque tool supplier, Industrial Bolting is known for its responsive, knowledgeable, and hands-on customer service that keeps industrial operations running smoothly.

Cut Downtime Costs with the Torque Command Center

In heavy industry, unplanned downtime means lost productivity and profit. That’s why businesses across the Midwest rely on Industrial Bolting’s Torque Command Center™. Whether you’re handling routine maintenance in Merrillville, IN, or urgent repairs in Muskego, WI, our fast-dispatch rental system and expert support get the tools you need on-site quickly, so you can stay […]

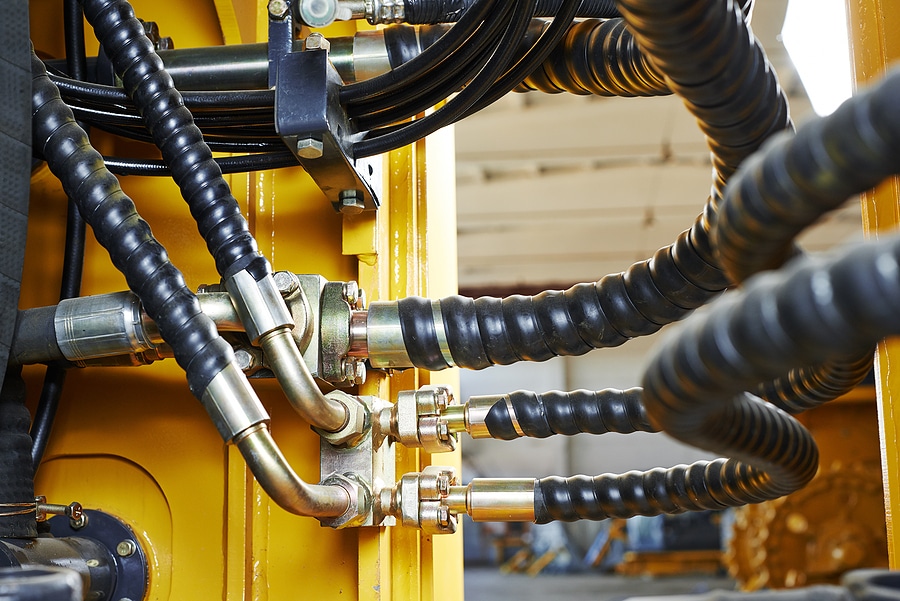

Don’t Let Hydraulic Tool Failure Shutdown Your Worksite

At Industrial Bolting, we recognize that hydraulic torque tools are the foundation of safe and efficient bolting operations in heavy industrial environments. When these tools begin to fail, the consequences can be costly, ranging from missed deadlines to dangerous mechanical failures. Recognizing the early signs of hydraulic tool failure can save your project from expensive […]

Spring Maintenance for Torque Tools: A Smart Start to the Season

Spring has arrived, ushering in a busy season when every tool must perform at its peak. After a long winter of storage or heavy use, your torque tools may need some essential attention. Regular maintenance—calibration, lubrication, and timely repairs—ensures your equipment operates smoothly and your operations remain uninterrupted. At Industrial Bolting, we understand that reliable […]