Category: Torque Tool Repair

Cold Weather, Hot Problems: Diagnosing Torque Tool Issues Fast

Industrial torque tools are built for demanding environments, but even the most reliable equipment eventually shows signs of wear. As colder temperatures settle across the U.S.—especially throughout the Midwest—hydraulic and pneumatic torque tools become more susceptible to performance issues. At Industrial Bolting, we provide expert torque tool calibrations and understand how winter conditions can thicken […]

Industrial Bolting: Trusted Industrial Tool Service and Support

In heavy industries where precision, safety, and uptime are critical, reliable support is essential. That’s why companies across America turn to Industrial Bolting. More than just a torque tool supplier, Industrial Bolting is known for its responsive, knowledgeable, and hands-on customer service that keeps industrial operations running smoothly.

Cut Downtime Costs with the Torque Command Center

In heavy industry, unplanned downtime means lost productivity and profit. That’s why businesses across the Midwest rely on Industrial Bolting’s Torque Command Center™. Whether you’re handling routine maintenance in Merrillville, IN, or urgent repairs in Muskego, WI, our fast-dispatch rental system and expert support get the tools you need on-site quickly, so you can stay […]

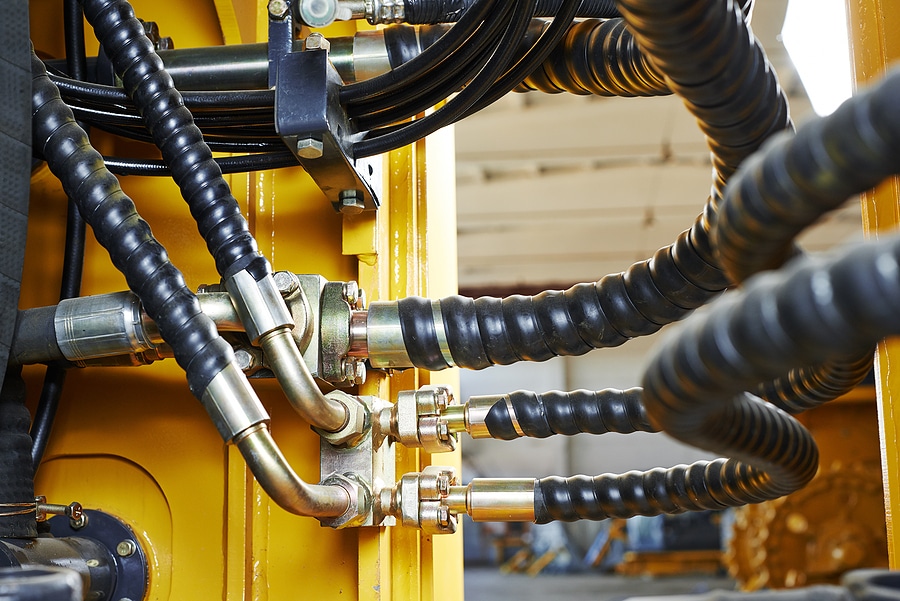

Don’t Let Hydraulic Tool Failure Shutdown Your Worksite

At Industrial Bolting, we recognize that hydraulic torque tools are the foundation of safe and efficient bolting operations in heavy industrial environments. When these tools begin to fail, the consequences can be costly, ranging from missed deadlines to dangerous mechanical failures. Recognizing the early signs of hydraulic tool failure can save your project from expensive […]

Avoid Bolt Galling with the Right Torque Process and Tools

Bolt galling, a type of adhesive wear, can cause significant problems for threaded fasteners during tightening, particularly in high-pressure, high-temperature, or stainless steel applications. The consequences include seized bolts, costly delays, and even damaged components. However, galling can be prevented with the right torque procedures and tools. Industrial Bolting is here to assist you in […]

Maximize Uptime with On-Site Support from Industrial Bolting

In industrial bolting applications, even minor setbacks, such as tool malfunctions, calibration discrepancies, or operator errors, can result in significant project delays and increased costs. At Industrial Bolting, we understand the importance of maintaining efficiency and minimizing downtime. We offer on-site technical support to deliver assistance precisely when and where you need it. Our skilled […]

Keep Your Tools in Top Shape: When to Seek Out Expert Repair

Torque tools are the backbone of countless industrial operations, ensuring precision, safety, and reliability in critical tasks. However, like any equipment, they can wear down over time, leading to inefficiencies, costly downtime, or even dangerous failures. Recognizing the signs that your torque tool needs repair is crucial for maintaining productivity, safety, and project success. At […]