Don’t Let Hydraulic Tool Failure Shutdown Your Worksite

At Industrial Bolting, we recognize that hydraulic torque tools are the foundation of safe and efficient bolting operations in heavy industrial environments. When these tools begin to fail, the consequences can be costly, ranging from missed deadlines to dangerous mechanical failures. Recognizing the early signs of hydraulic tool failure can save your project from expensive downtime and protect your team from unnecessary risk.

Common Warning Signs of Hydraulic Tool Failure

Pressure Drops or Inconsistent Force

One of the most common signs of trouble is a drop in pressure or inconsistent torque output. If your hydraulic wrench isn’t delivering consistent force, the seals, valves, or pump may be compromised.

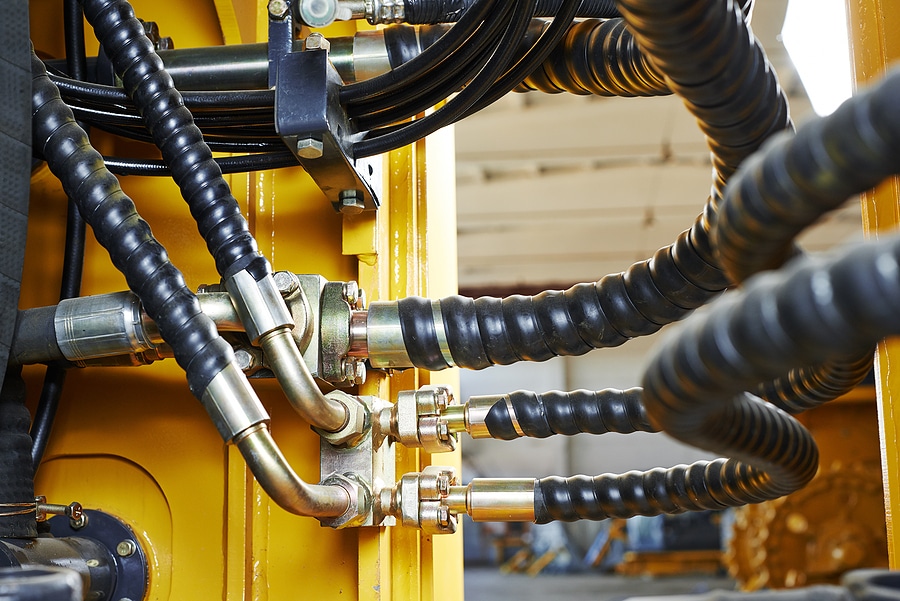

Fluid Leaks or Hose Damage

Wear and tear, as well as contamination, often cause leaks around fittings or damaged hoses. These issues are messy, reduce tool efficiency, and create slipping hazards on the job site.

Slow or Sluggish Tool Operation

If your hydraulic tools are operating more slowly than usual, you may be dealing with internal wear, a clogged filter, or degraded hydraulic fluid. Don’t ignore sluggish performance—it’s a red flag that the system is struggling.

Excessive Heat During Use

Hydraulic tools naturally warm up with use, but overheating is a sign of trouble. It could indicate low fluid levels, blocked lines, or overuse without proper maintenance.

Strange Noises or Vibrations

Unusual sounds, such as knocking or grinding, can indicate internal damage. Persistent vibration could mean loose components or worn-out couplings.

Why Early Detection Matters

Waiting until your torque tools fail completely can halt production and delay your project by days or weeks. In industries where uptime is everything, proactive maintenance and repair are critical.

How Industrial Bolting Can Help

Our team offers professional services related to hydraulic torque tools for heavy industrial companies across the United States.

- We provide torque tool calibrations on-site or in-house at one of our Midwest locations.

- Our team offers fast turnaround repairs with OEM-certified parts.

- We supply tool rentals to keep your job site moving while your tools are serviced.

- We offer tool sales and upgrades if your equipment is beyond repair.

Our technicians are here to extend the life of your equipment and reduce unexpected failures.

Don’t Wait for a Breakdown

If your hydraulic torque tools show signs of wear or underperformance, now is the time to act. We proudly serve industrial clients across the United States from our locations in Indiana, Illinois, Ohio, and Wisconsin, delivering expert services rooted in decades of field experience.

Whether you need fast, reliable repairs or high-performance rentals and sales, our team is committed to helping you minimize downtime and maximize safety. Contact us at (888) 781-2007 to schedule service or find the right replacement tool. At Industrial Bolting, we believe in doing the job right the first time with the right tools and the right team.

Casey, Brendan. 2003. “Symptoms of Common Hydraulic Problems and Their Root Causes.” Machinery Lubrication, September. https://www.machinerylubrication.com/Read/531/hydraulic-root-causes.