Tag: Hydraulic Torque Tool Maintenance

Cold Weather, Hot Problems: Diagnosing Torque Tool Issues Fast

Industrial torque tools are built for demanding environments, but even the most reliable equipment eventually shows signs of wear. As colder temperatures settle across the U.S.—especially throughout the Midwest—hydraulic and pneumatic torque tools become more susceptible to performance issues. At Industrial Bolting, we provide expert torque tool calibrations and understand how winter conditions can thicken […]

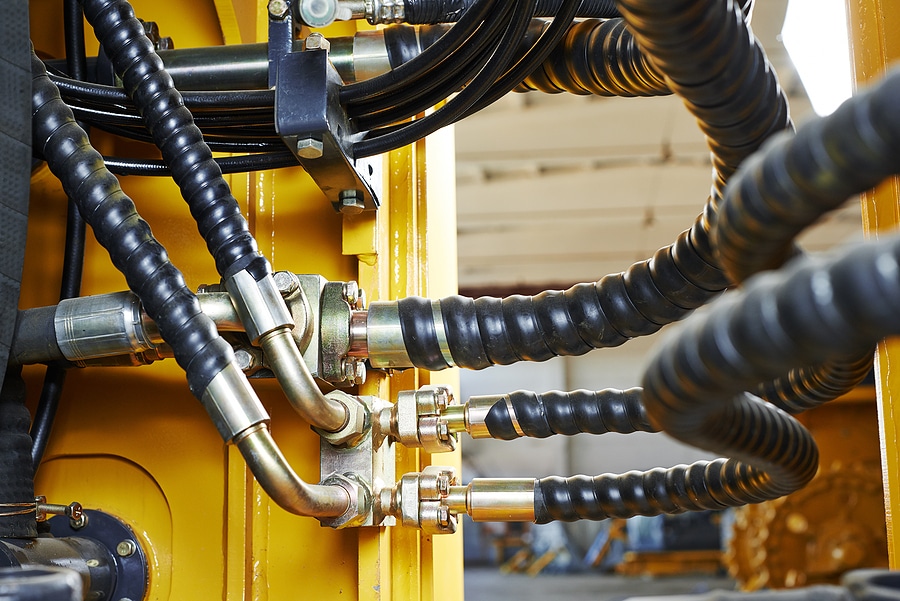

Don’t Let Hydraulic Tool Failure Shutdown Your Worksite

At Industrial Bolting, we recognize that hydraulic torque tools are the foundation of safe and efficient bolting operations in heavy industrial environments. When these tools begin to fail, the consequences can be costly, ranging from missed deadlines to dangerous mechanical failures. Recognizing the early signs of hydraulic tool failure can save your project from expensive […]

Maximize Uptime with On-Site Support from Industrial Bolting

In industrial bolting applications, even minor setbacks, such as tool malfunctions, calibration discrepancies, or operator errors, can result in significant project delays and increased costs. At Industrial Bolting, we understand the importance of maintaining efficiency and minimizing downtime. We offer on-site technical support to deliver assistance precisely when and where you need it. Our skilled […]