Recent Articles

Avoid Joint Failures This Summer With Proper Torque Tensioning

When summer temperatures climb, so does the risk of joint failures in heavy industrial equipment. Elevated heat levels, combined with prolonged stress, can cause bolted connections to loosen or deform, leading to hazardous outcomes such as equipment misalignment, breakdowns, or even catastrophic failures. For industries operating in the Midwest—especially those in Indiana, Illinois, Ohio, and […]

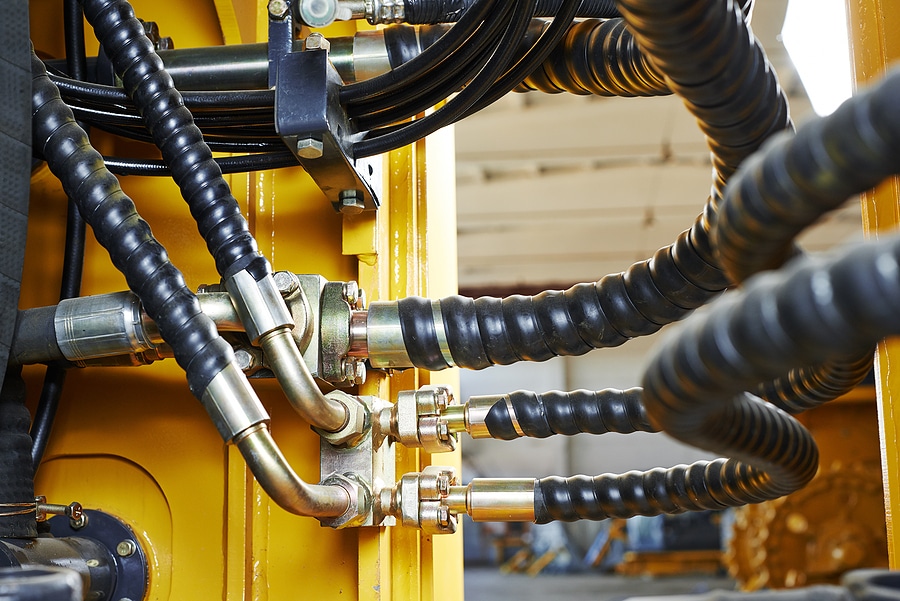

Don’t Let Hydraulic Tool Failure Shutdown Your Worksite

At Industrial Bolting, we recognize that hydraulic torque tools are the foundation of safe and efficient bolting operations in heavy industrial environments. When these tools begin to fail, the consequences can be costly, ranging from missed deadlines to dangerous mechanical failures. Recognizing the early signs of hydraulic tool failure can save your project from expensive […]

Avoid Bolt Galling with the Right Torque Process and Tools

Bolt galling, a type of adhesive wear, can cause significant problems for threaded fasteners during tightening, particularly in high-pressure, high-temperature, or stainless steel applications. The consequences include seized bolts, costly delays, and even damaged components. However, galling can be prevented with the right torque procedures and tools. Industrial Bolting is here to assist you in […]

Industrial Turnarounds Made Easy with Expert On-Site Support

Turnarounds and shutdowns are necessary in industrial facilities to ensure equipment operates at peak performance and complies with industry regulations. However, these intricate processes can pose significant challenges, requiring meticulous planning and execution to avoid costly delays and safety hazards. Industrial Bolting offers expert on-site technical support to transform potential disruptions into seamless transitions.

4 Things to Know Before You Rent or Buy a Torque Wrench

Choosing the right hydraulic torque wrench is critical for any high-torque bolting application, whether maintaining pipelines, working in a wind turbine, or installing industrial machinery. But should you rent or buy? At Industrial Bolting, we provide expert insights and a full range of torque tools, including American-made hydraulic torque wrenches, available for sale or rent at […]

Heat Smarter, Work Faster: The Power of Induction Bolt Heating

As work ramps up with the arrival of spring, ensuring your bolting equipment performs at its peak is essential. Induction bolt heating offers a solution that surpasses traditional flame-based methods for teams that demand precision and efficiency in heavy-duty fastening. Trusted by professionals across the Midwest, Industrial Bolting has earned its reputation by consistently delivering […]

Spring Maintenance for Torque Tools: A Smart Start to the Season

Spring has arrived, ushering in a busy season when every tool must perform at its peak. After a long winter of storage or heavy use, your torque tools may need some essential attention. Regular maintenance—calibration, lubrication, and timely repairs—ensures your equipment operates smoothly and your operations remain uninterrupted. At Industrial Bolting, we understand that reliable […]

Torque Tension Training: The Key to Reliable Plant Maintenance

In the high-stakes world of industrial maintenance, precision isn’t just a preference—it’s a necessity. At Industrial Bolting, we understand that proper torque tension is essential for maintaining the integrity and reliability of critical equipment, from pipelines to heavy machinery. Without expert training and the right tools, maintenance teams risk costly downtime, structural failures, and safety […]

The Hidden Costs of Uncalibrated Torque Tools in Heavy Industry

Precision is crucial in heavy industrial operations. At Industrial Bolting, we’ve seen firsthand how uncalibrated torque tools can quietly compromise safety, productivity, and compliance across demanding sectors like energy, manufacturing, and infrastructure. In reality, tools that appear functional may deliver inaccurate torque, leading to costly equipment damage, regulatory issues, and unplanned downtime.

Make Smart Decisions for Your Bolt Load Testing Equipment Needs

Precision is everything when it comes to industrial bolting. Even the slightest miscalculation in bolt tension can compromise structural integrity, safety, and performance. At Industrial Bolting, we support industries like construction, manufacturing, and energy with reliable bolt-testing solutions designed for uncompromising accuracy. When selecting a bolt tension calibrator, one important question often arises: Should you […]